CellScrew®

Single-use device for adherent cells cultures with a high growth area to volume ratio and made from plant-derived PLA by an additive manufacturing process

Our videos

Specifications

The CellScrew®’s features unique internal structures, including an Archimedes Screw and concentric cylinders, which create a low-shear stress mixed system. This design facilitates high oxygenation and efficient nutrient exchange, promoting optimal adherent cell attachment and growth.

- Adherent cell cultures

- R&D, pilot and production scales (GMP certification soon available)

- CS10K : Cell culture area 10.000 cm² – Media volume: 800 – 1.000 mL

- CS6K : Cell culture area: 6.000 cm² – Media volume: 500 – 600 mL

- Large cell culture area formed by concentric cylinders

- Compact design – easy handling and saves incubator space

- Great automation potential

- Excellent mixing and gas exchange through an Archimedean screw

- More sustainable than conventional multilayer flasks

By rotation of the CellScrew®, media and gas are transferred through an Archimedean screw, providing an excellent environment for the cells. Concentric cylinders form the large growth area. Due to TC-treatment, the surface is ideal for cell attachment and growth.

Features

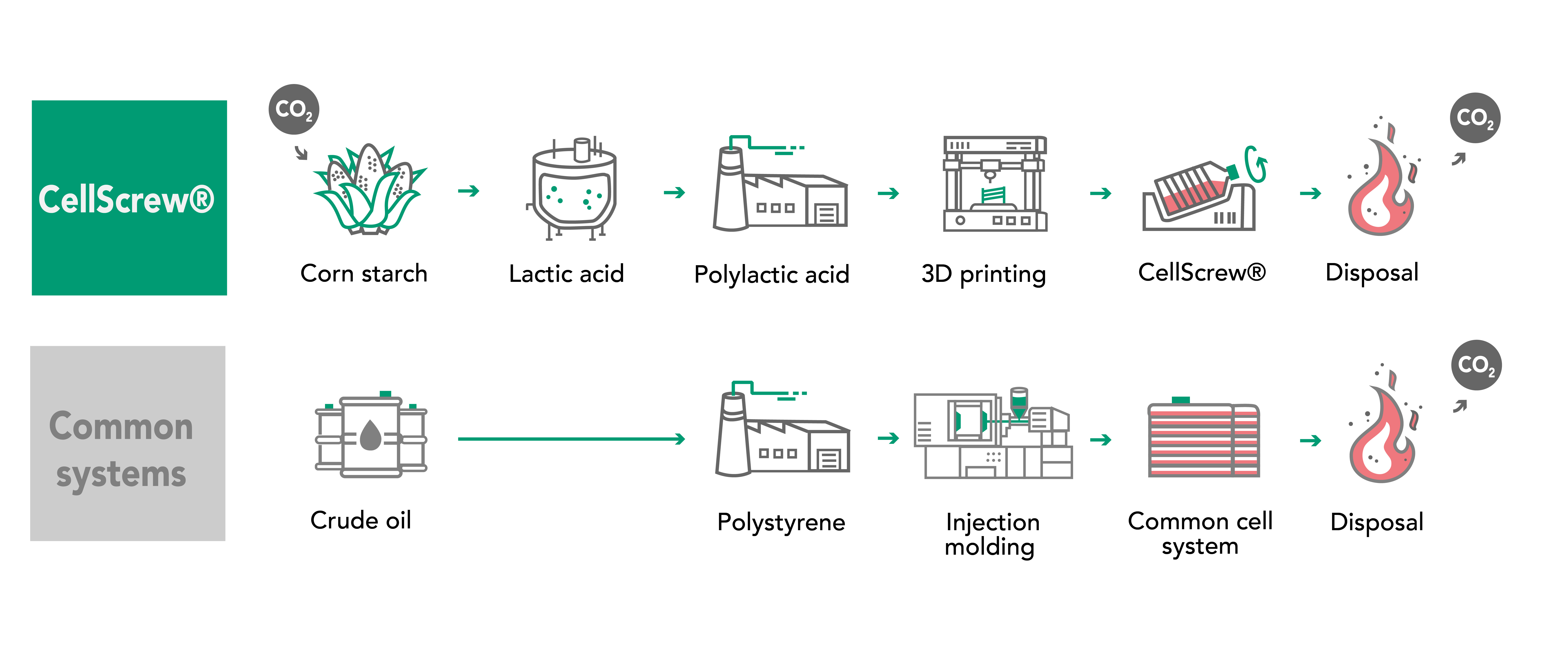

The CellScrew® is made of poly-lactic acid (PLA), a plant-based biopolymer produced entirely from renewable crops.

Product benefits

Reduced manufacturing costs

The large growth area, intensified processes and ease of handling reduce labour costs and required manufacturing space.

Reduced time to market

As the CellScrew® can be applied from lab scale to manufacturing scale, no additional process development is necessary to scale-up.

Reduced environmental impact

CO₂ emission is reduced by more than 90% using the CellScrew®, compared to conventional multilayer flasks as it is made from plant-derived PLA by an additive manufacturing process.

Technical data

The CellScrew®’s utilizes an Archimedes Screw that transfers the medium within the bottle by slow rotation. A tube in the middle allows the medium to flow to the bottle’s bottom, creating a circular media flow. This, combined with continuous mixing on a roller bottle device, ensures excellent oxygen transfer and optimal cell cultivation conditions for your adherent cell lines.

- Green Elephant Biotech GmbH CellScrew® 6k, GEB-CS-6k: TC treated surface, with filter cap

- Weigth : 385 g

- Theoretical total volume : 1360 mL

- Working volume : 500 – 600 mL

- Growth area : 6,066 cm²

- Mixing time : < 9 min (@0.5 rpm)

- Heigth : 191.88 mm

- Diameter : 120 mm

- Cylinder height : 136.43 mm

- Konus height : 32 mm

- Konus angle : 34.78 °

- Cap diameter : 39 mm

- Cap height : 24 mm

- Green Elephant Biotech GmbH CellScrew® 10k, GEB-CS-10k: TC treated surface, with filter cap

- Weigth : 600 g

- Theoretical total volume : 2193 mL

- Working volume : 800 – 1,000 mL

- Growth area : 10,313 cm²

- Mixing time : < 27 min (@0.5 rpm)

- Heigth : 283.88 mm

- Diameter : 228.43 mm

- Cylinder height : 120 mm

- Konus height : 32 mm

- Konus angle : 34.78 °

- Cap diameter : 39 mm

- Cap height : 24 mm

- Packaging dimensions : 130 mm x 130 mm x 300 mm

- Material : Polylactic acid

- Color : Translucent

- Sterilization method : Gamma irradiation

- Operating temperature : 2 °C to 45 °C

- Storage : Room temperature

- Centrifugability : No

- Autoclavability : No

- Recommended rotating speed : 0.5 – 2 rpm

- kLa – value : 1.95 h-1 (@0.5 rpm)

- Shelf life : 12 months

- Packing unit : 1 CellScrew®, 1 bag of 1 piece

Gallery

Ask a demo

Make an appointment with one of our experts to find out how our solutions will help you improve your bioprocesses