PAK System

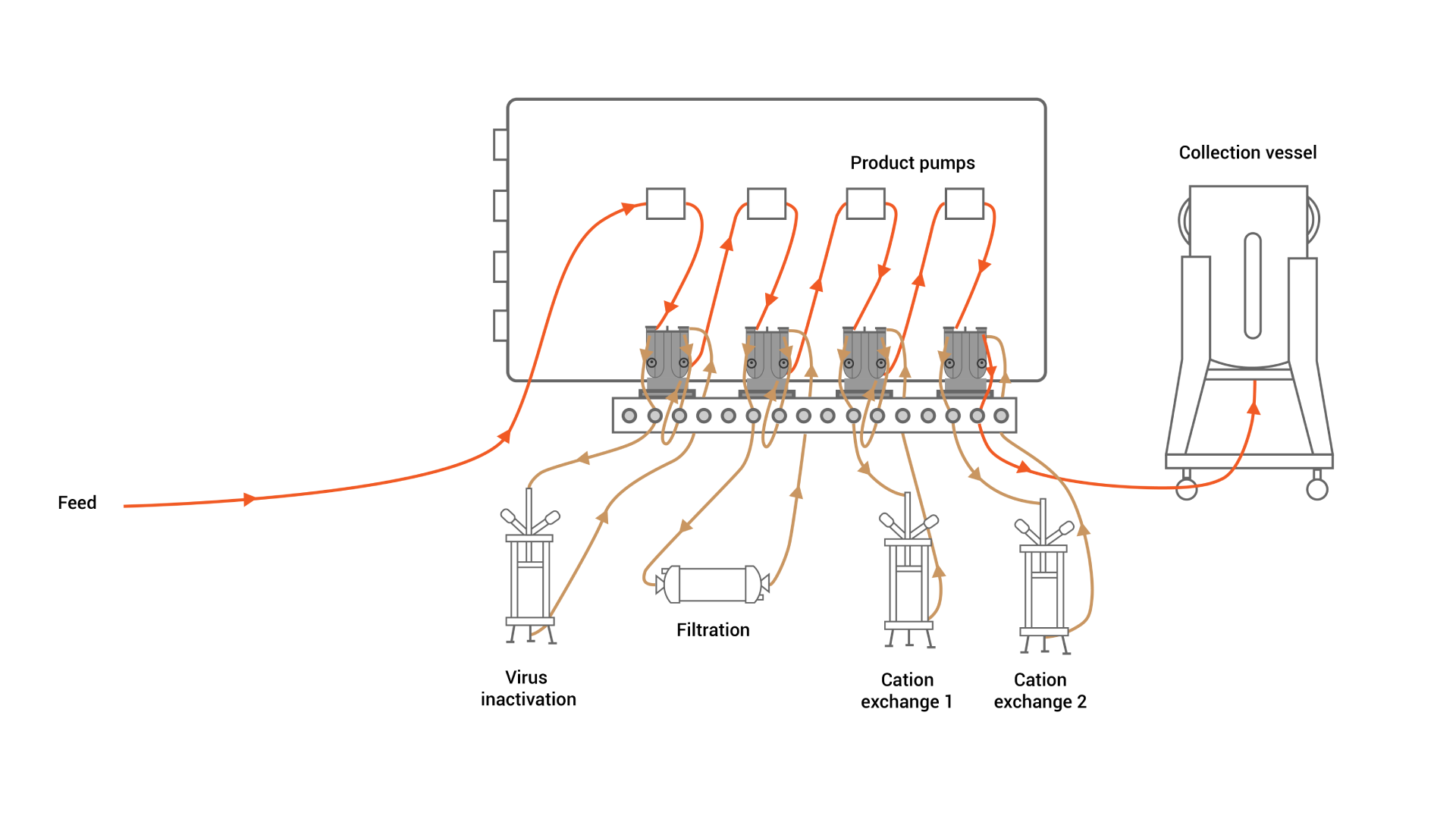

Single-use platform to perform 4 continuous unit operations simultaneously

Our videos

Specifications

Automation controls flow from one step to the next and the mass flow rate of the entire process for purification of 50 to 500 L of cell culture per day.

- R&D

- Pilote

- Production

- GMP

- Diafiltration

- Chromatography

- Viral Inactivation

- Inline Concentration

- Filtration

- Monoclonal antibodies and other biopharmaceuticals

- Realize over 4-fold productivity improvement and 50% reduction in capital requirements when compared to batch processes

- Reduce hold tank volumes over 100-fold by simultaneous operation of purification steps in series

- Connect multiple skids in series to operate an entire downstream process continuously, with instrumentation and buffer management seamlessly integrated

- Select any order of unit operations and update operating parameters in minutes with PurSyncTM dynamic automation package

- Simplify setup with our solid, single use flow kit that includes all tubing connections, static mixers, instrumentation ports and a break vessel in one ergonomic design

- Ensure compliance with 21 CFR Part 11 automation and product contact materials that meet USP Class VI testing requirements

The PAK system is designed for simultaneous operation of four sequential purification steps for monoclonal antibodies and other biopharmaceuticals: diafiltration, chromatography, viral inactivation, inline concentration, filtration

- Virus inactivation steps are a critical component of biopharmaceutical purification processes. Continuous virus inactivation in the PAK system is achieved with inline pH adjustment or inline addition based on a volumetric ratio for detergent. Flow through a residence chamber provides the specified hold time to achieve the required virus log reduction values (LRV)

- Additional highlights of the systems capabilities include:

- Continuous monitoring of pH and residence time to ensure out-of-spec material is not directed to the downstream purification stage

- Inline pH, conductivity, or volumetric ratio buffer addition at the outlet of the virus inactivation step to meet target ranges for the subsequent stage

- Flow-through filtration steps include a 0.2 µm filter, depth filter, virus filter, or anion exchange membrane, among others

- For these steps, the PAK System monitors the totalized process throughput, notifies the user when the membrane is nearing maximum capacity, and pauses the process if capacity is reached

- Filters are often specified for once or twice daily replacement to not exceed capacities. The PAK system allows for inline buffer adjustments at the inlet and outlet of the step based on pH, conductivity or volumetric ratios

- Back pressure control can also be performed with variable position pinch valves

- A dual column chromatography step enables bind and elute chromatography to be performed in a semi-continuous manner

- Two stages of the system can be configured to perform a dual column chromatography step

- The first product pump of the two stages continuously feeds product intermediate from the upstream step onto one of the two columns where it binds to the resin. A sequence of buffers is flushed through the other column to remove impurities or elute product intermediate. After the buffer cycle is completed and the column in the load step has reached capacity, the two columns switch positions

- The system provides gradient capabilities as well as inline dilution to reduce buffer tank volumes

- Two UV wavelengths can be monitored simultaneously, with a single wavelength and/or column volume set points used for elution collection criteria

- The elution collection vessel is sized for at least five elution volumes and mixed to ensure material supplied to the next stage is consistent and does not result in a spike in product concentration, pH or conductivity during an elution step

- Concentration steps are performed with single pass tangential flow filtration (SPTFF)

- Achieve target concentration factor with a variable pinch valve for back pressure control

- Calculate concentration factor based on flow rate ratios or monitor density with the single-use mass flow meter

- A series of concentration and dilution steps, typically two or more, are performed in series to perform diafiltration or buffer exchange

- A single PAK System can perform three concentration and dilution steps in series, followed by a final concentration step, to achieve the concentration and diafiltration targets of a traditional batch ultrafiltration/diafiltration (UFDF) process with greater than 99.75% buffer exchange

Synchronous operation is achieved with four control schemes: mass flow control, flow kit vessel level control, dual column vessel level control, and high-low level control

- The mass flow control scheme controls the last product pump in the series to a flow rate set point, which sets the overall mass flow rate of the entire process

- This flow rate set point adjusts based on the monitored flow rate of a critical unit operation

The flow kit vessel level control scheme continuously controls all upstream product and buffer pumps to ensure constant levels in the small break vessels between each process stage

- The dual column vessel level control scheme periodically adjusts the product and buffer flow rates of the chromatography step to ensure the outlet vessel level of this stage remains within an acceptable range

- Since the fill of this vessel is periodic rather than constant (when an elution step occurs), the dual column vessel level control and associated buffer and product pump flow rate adjustments occur only one time at the start of each load cycle

Vessel high-low level control stops the pumps from running when vessels reach their minimum or maximum levels, in extreme circumstances

Features

Multiple skids can be connected in series to operate an entire downstream process continuously, with required instrumentation and buffer management seamlessly integrated.

Product benefits

End-to-end continuous purification

Realize over 4-fold productivity improvement compared to batch processes thanks to simultaneous operation of four sequential purification steps.

Reduced volumes and costs

50% reduction in capital requirements compared to batch processes.

Up to 100 fold reduction in tank volumes thanks to simultaneous and serial operation.

Automation

All stages are controlled automatically and in accordance with CFR21 part11 with PurSyncTM dynamic automation package.

Single-use

One of the best features of The PAK System is the easy setup.

The flow kit assembly combines all fluid management components and instrumentation into a single-use unit for quick installation.

Technical data

- 36 valves

- 8 pumps : 4 buffer pumps + 4 product pumps

- 8 pH or conductivity sensors

- 8 pressure sensors

- 6 scales

- 2 dual wavelength UV meters

- 2 single use mass flow meters

- 500 ml

- Quick setup in the Pilot PAK™ continuous purification system

- Solid flow kit includes : Connections for two pH and/or conductivity meters, Connection for one UV meter, Two static mixers for inline pH adjustment or inline dilution, One mixing vessel with one vent, two hose barb inlet/outlet ports and one 3/4” sanitary port

- Materials of construction: Nylon 12 and fused silica

- Materials meet USP Class VI and/or ISO 10993 specifications

- Gamma compatible

Automation that is 21 CFR Part 11 compliant and product contact materials of construction that meet USP Class VI

Gallery

Ask a demo

Make an appointment with one of our experts to find out how our solutions will help you improve your bioprocesses